Unleashing Creativity: The Magic of DTF Printing

In recent years, the world of printing has seen an exhilarating transformation, with various techniques emerging to meet the growing demand for high-quality and versatile image transfers. One of the most captivating advancements in this field is DTF printing, which stands for Direct to Film. This innovative method allows creators to unleash their artistic visions onto a wide range of fabrics with stunning ease and precision. As the creative industry continues to evolve, the popularity of DTF printers is skyrocketing, making them a vital tool for designers, businesses, and hobbyists alike.

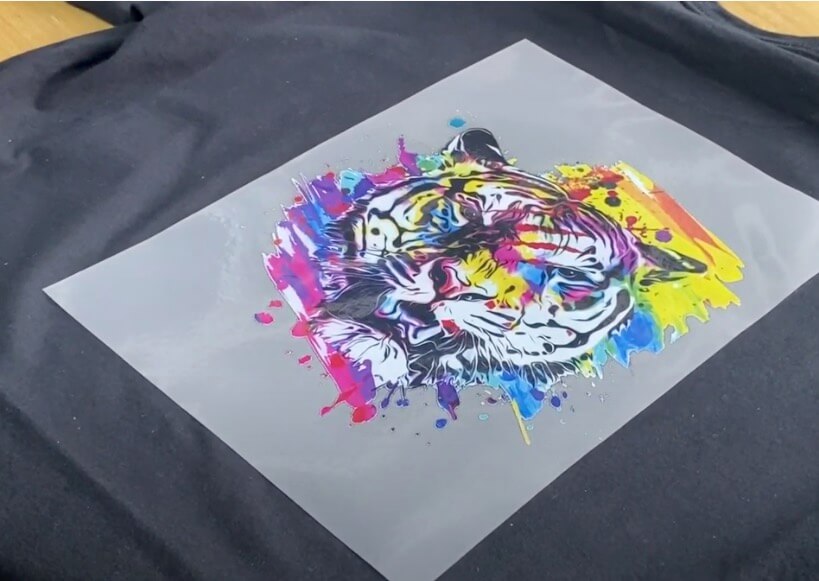

What makes DTF printing particularly enchanting is its ability to produce vibrant colors and intricate designs that adhere seamlessly to different materials. Whether you are looking to customize apparel, create unique promotional items, or explore new artistic avenues, an imprimante DTF can be your gateway to endless possibilities. The blend of creativity and technology in this printing method opens doors for personalized expressions, enabling everyone from small business owners to professional artists to bring their ideas to life like never before.

Understanding DTF Printing Technology

DTF printing, or Direct to Film printing, is a revolutionary process that allows for vibrant, high-quality designs to be transferred onto various surfaces, primarily fabrics. This technique involves printing an image onto a special film, which is then coated with a specific adhesive powder. The process combines the best aspects of both direct printing and transfer methods, providing a versatile solution for creating intricate designs with excellent durability.

One of the core benefits of using an imprimante DTF is its ability to work effectively on a wide range of materials, including cotton, polyester, and blends. This adaptability makes DTF printing an appealing option for fashion designers, promotional products, and even personal customization. The technology permits the printing of detailed images with a wide color gamut, ensuring that every project can achieve its desired look without compromising on quality.

Additionally, the production efficiency associated with DTF printing cannot be overlooked. The process is relatively simple and quick compared to traditional screen printing. Once the film is printed, the design can be heat-pressed onto the fabric, which drastically reduces the time required for setup and production. This efficiency has made imprimante DTF a popular choice for businesses looking to streamline their operations while still offering high-quality printed products.

Applications of DTF Printing

DTF printing has gained popularity in various industries due to its versatility and high-quality output. One of the most prominent applications is in the fashion and apparel sector, where custom designs can be printed on a wide range of textiles. From t-shirts to hoodies, the ability to produce vibrant colors and intricate details allows brands to bring their creative visions to life. This technology enables small businesses and independent designers to offer unique, personalized clothing options that appeal to a diverse audience.

Beyond fashion, DTF printing is making waves in promotional products. Companies are increasingly utilizing this method for custom merchandise, such as tote bags, hats, and giveaways. The durability of DTF prints ensures that these products maintain their vivid appearance even after multiple washes, which is a significant advantage for businesses seeking to make a lasting impression. This application not only enhances brand visibility but also provides an effective means of engaging customers through personalized items.

Additionally, DTF printing is finding its place in interior decoration. Home décor items like cushions, wall art, and decorative blankets can be customized with meaningful designs, making spaces more personal. The ability to print on various fabrics broadens the creative possibilities for interior designers and DIY enthusiasts alike. As DTF technology continues to evolve, its applications are likely to expand further, enticing more industries to explore this innovative printing method.

Benefits of Using DTF Printers

DTF printers offer exceptional versatility, enabling users to print on a wide variety of materials. dtg printing Unlike traditional printing methods that may limit you to specific fabrics, DTF printing allows for work on cotton, polyester, and blends. This flexibility opens up numerous possibilities for creating custom apparel, accessories, and home decor. Whether you are a small business owner or a hobbyist, the ability to print on diverse surfaces expands your product range and appeal.

Another significant benefit is the high-quality output that DTF printers can achieve. The technology uses a unique ink transfer process that ensures vibrant colors and intricate details, resulting in stunning designs. The prints are not only visually striking but also durable, as they can withstand multiple washes without fading or peeling. This reliability makes DTF printing an attractive option for those looking to produce long-lasting items.

Finally, DTF printers streamline the production process, making it more efficient. With the ability to create transfers that can be applied to garments quickly, businesses can significantly reduce production times. This efficiency, combined with lower setup costs compared to other methods like screen printing, allows for quicker turnaround times and more significant profit margins. Embracing DTF printing can lead to increased customer satisfaction and a strong competitive edge in the market.